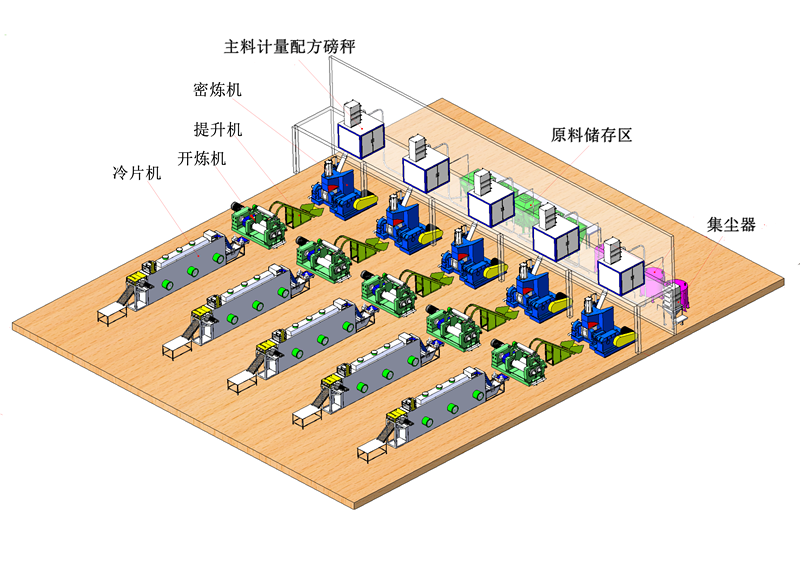

Mixer Feeding System

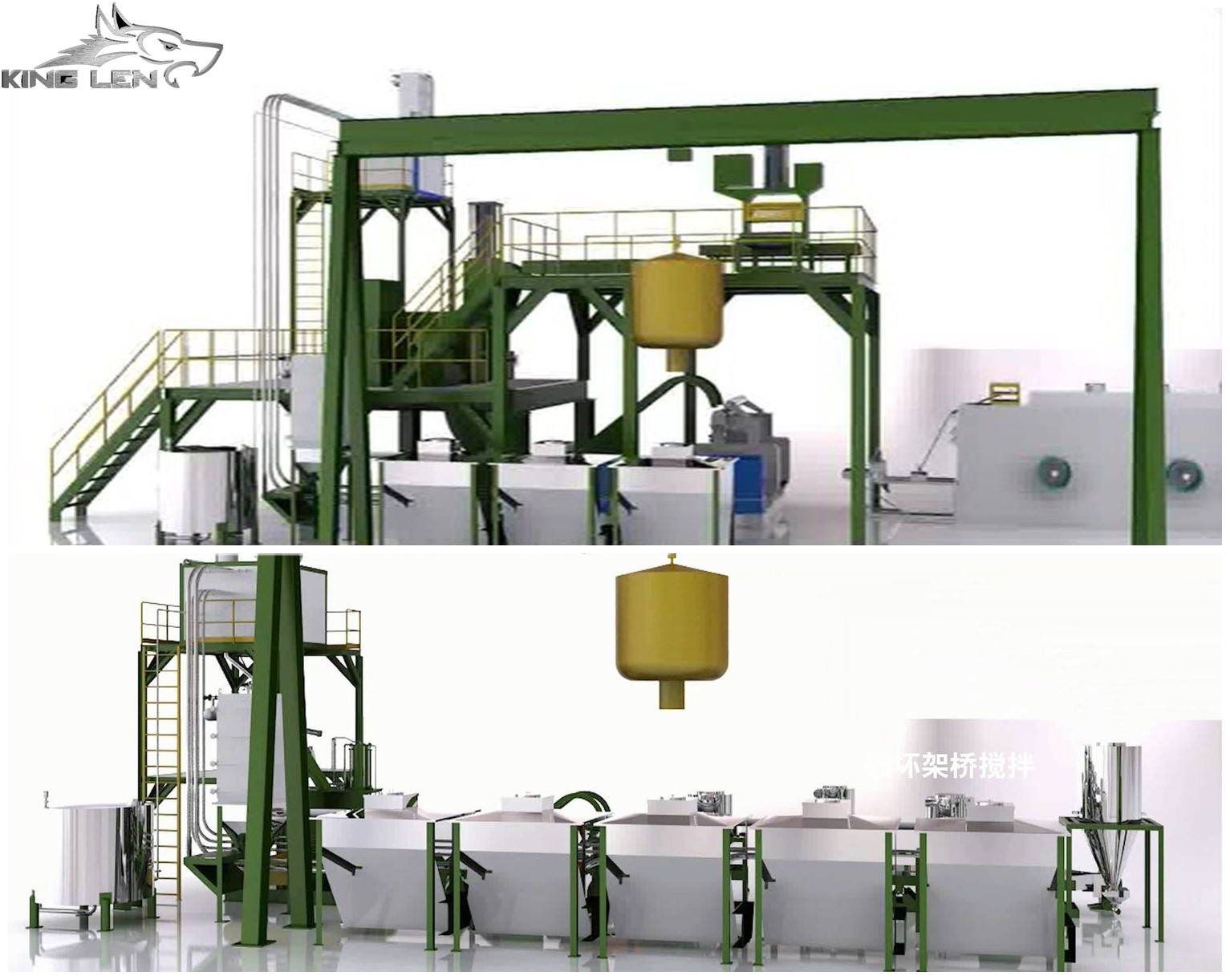

The system is mainly suitable for the first and second-story structure workshops, in which the main materials are conveyed and measured by negative pressure suction. It is mainly composed of raw material storage system, conveying pipeline, automatic metering system of raw material formula, dust collector and computer control system. Meet the requirements of the internal mixer/kneader host for the storage, transportation, metering, batching, feeding and dust removal of various raw materials (carbon black, powder, liquid, rubber), and realize the integration with internal mixers and kneaders Linkage control of the host. Mainly used in the production of rubber products, plastic products, cable materials, food, medicine, chemical raw materials and other products.

The system’s process layout is flexible, the plant investment cost is low, and the bulk material handling links are reduced. The raw material storage and unpacking are separated from the production area, and the environment is clean; the unpacking device uses a single machine to remove dust, no raw material loss, and realizes production automation and management information . It can satisfy users' misplacement of raw materials, real-time monitoring and historical playback of the production process, storage and recall of data (material library, recipe library, mixing process parameters, etc.) and reports (car report, daily report, mixing curve, etc.), and production plan Manage and provide various functional requirements such as MES/ERP excuses. Ability to develop management and control systems with rich functions, strong pertinence, reliable and practical for different users.